Specifications:

Order no. | Range | Resolution | Accuracy |

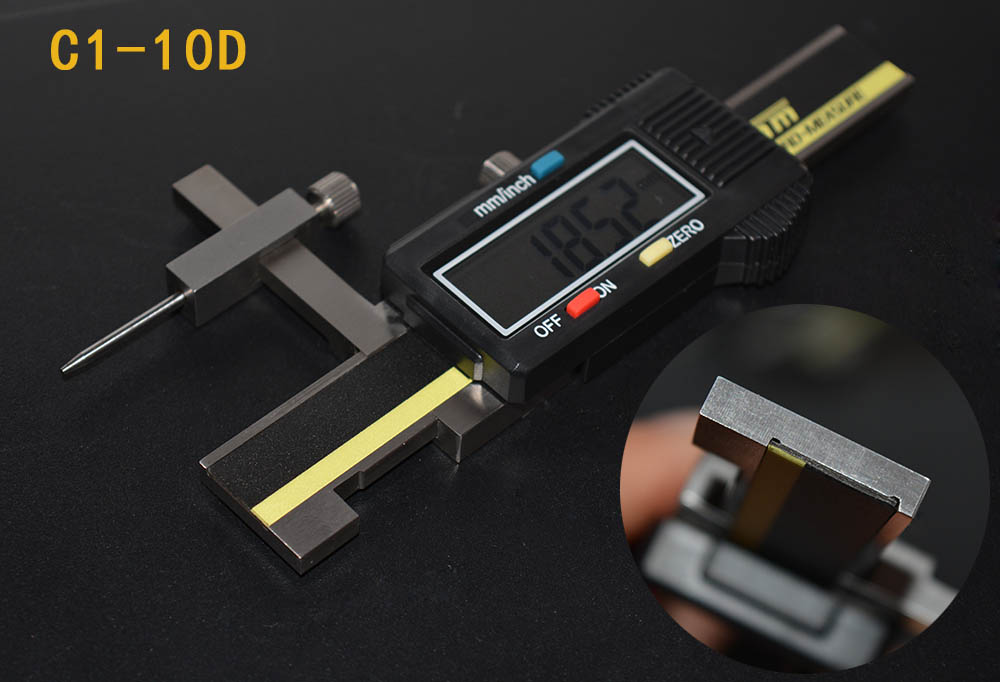

C1-10D | 0±10mm | 0.01mm | ±0.03mm |

C1-15D | 0±15mm | 0.01mm | ±0.03mm |

C1-20D | 0±20mm | 0.01mm | ±0.03mm |

C1-25D | 0±25mm | 0.01mm | ±0.03mm |

Features:

1. Flat and thin measuring base with needle probe, can measure narrow gap.

2. Button: on/off, zero, metric system conversion.

3. Large LCD screen makes the reading more intuitive.

4. Power supply: 1.5v LR44 button battery x 1

5. With data output, optional data line which can connect with computer to collect data. Wireless data transmitter also available to transfer data directly to the excel or word files.

6. All the gap / step gauge are designed with different measuring bases to match various measuring surfaces, pls choose the right model according to your measuring need, depends on the surface to be measured is smooth, narrow or curved.

Application:

* In the mold manufacturing, the gaps/steps refers to the matching deviation of two pieces of mold inserts or the parting surface position of front and rear molds due to the processing accuracy deviation; In automobile production, the gaps/steps refers to the existence of matching error when parts are assembled, the two planes of the joint is not smooth. Complex the gaps/steps measurement is always a difficult problem to deal with. However, the various gap/step gauges of TIMM can offer an excellent solution to various matching errors, height differences, gaps of two adjacent surfaces.

* The latest digital gap/ step gauge, with simple design, Large LCD screen and data output, which make the operation easier, reading more intuitive and more convinient to collect real-time measuring data into the computer for processing and analysis, in which way you can well control the quality of your procuct.

* Digital gap/step gauges are widly used in mould manufacturing, Automobile industry and Mechanical processing industry.